Metal Hydride Air Conditioners

Continuous improvements in mobile air conditioners powered by exhaust heat

|

|

|

1994 - 9,000 BTU/h at 45F using exhaust heat 75 lb. |

2004 - 8,000 BTU/h at 47F using exhaust heat |

|

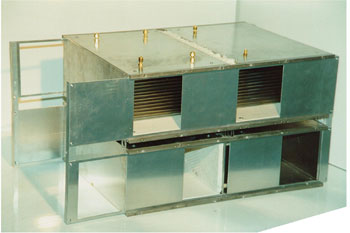

These air conditioners have two hydride heat exchanger beds. Each bed contains individual, hermetically sealed hydride tubes, 500 0.125” diameter tubes in the 1994 unit and 600 0.0625” diameter tubes in the 2004 unit. Each tube is essentially a miniature air conditioner, with one half containing a high pressure (cooling) alloy and the other half containing a low pressure (regenerating) alloy. When one of the beds is cooling passenger compartment air, the other is being regenerated by hot exhaust gas. Ambient air provides the heat rejection function. Sliding gate valves direct the air flows to the appropriate hydride section. Efficiency is on the order of 1 BTU of cooling for each 3 BTU of heat input. |

|

Electrically powered hydride air conditioner delivers outstanding performance |

|

|

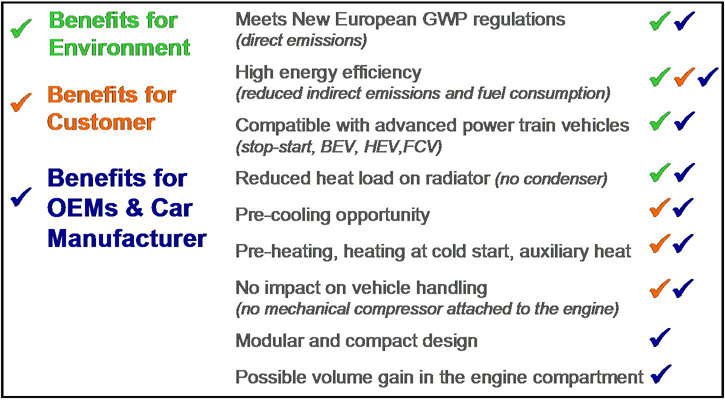

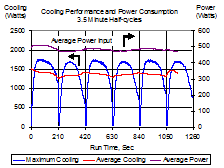

With Centro Ricerche Fiat (Torino, IT) Ergenics developed an electrically powered hydride air conditioner proof-of-concept prototype as a possible replacement for traditional mobile air conditioners. The unit does not contain materials with global warming potential and thus meets European Union guidelines for eliminating R-134a by the year 2011. The unit operated with more than twice the efficiency of today’s automotive air conditioners. Prototype Specifications: Prototype Performance: Total Input Power 485 W (Includes Compressor + 2 Fans + Controls) |

|