Metal Hydride Hydrogen Compressors

Ergenics has been supplying metal hydride hydrogen compressors for a broad range of applications for over twenty years. Compression of hydrogen using reversible metal hydride alloys offers an economical alternative to traditional mechanical hydrogen compressors. Hydride compressors are compact, silent, do not have dynamic seals, require very little maintenance and can operate unattended for long periods. When powered by waste heat, energy consumption is only a fraction of that required for mechanical compression, which reduces the cost of hydrogen production. The simplicity and passive operation of the hydride compression process offer many advantages over mechanical compressors.

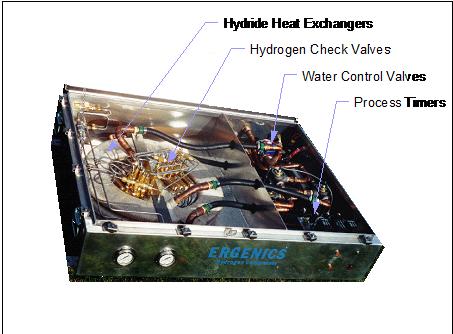

| These Ergenics’ hydride compressors use the thermal energy in hot water to compress hydrogen. If hot water is not readily available, a closed loop heating/cooling system can be supplied. Hydride compressors are custom designed to allow integration with your hydrogen process. |

Four stage, 90 SCFH Hydride Compressor. |

This six stage hydride compressor boosts pressure from atmospheric to 3,000 psia using energy from 85°C hot water! |

|

This hydrogen Micro-compressor is powered by electrical resistance heating. |

|